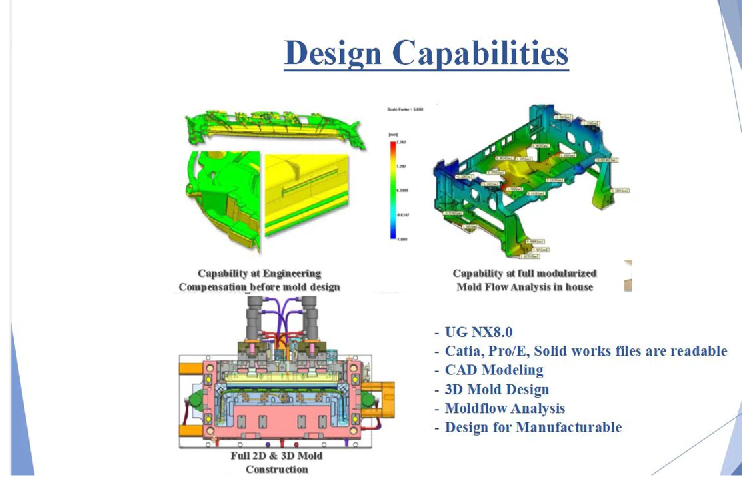

“The long journey begins with the first step”. The quality mould construction begins with a sound designs. At JS MOULD we strive to design the molds that are robust in nature, with focusing on minimizing both in cycle time and easy maintenance. We utilize over 20 full-time mold designers who are professional in designing injection molds with various standards. All plastic injection mold design are done in both 2D and 3D. A full 3D design is supplied with every mold. And all the mold designs are reviewed by our experienced technical team and project manager prior to submitting to customer for approval. Supplemented by the most advanced moldflow software , we are able to shorten the engineering timing and further supporting the feasibility of design. In order to meet and exceed the customer expectations, we continually strive to improve and enrich our services by introducing fresh approaches and innovative ideas. JS MOULD is able to keep the products in both integrity and accuracy sufficiently by using CAD/CAE/CAM technology. We blend the skills and thinking from our people with advanced technology using, it makes us be able to quickly respond the on-going marketing changes and positive face to our customers.

Operation flow: Data receiving, DFM analysis,MoldFlow analysis, Pre-warpage engineering,3D tooling construction, reviewing, optimization, submission

Data exchange: UG, PRO/E, SOLIDWORKS, CAITA, CAD, Part, STP, X_T, IGS, DWG, DXF, PDF, etc.

Regarding the workflow, we usually have DFM, Mold 3D/2D design and Mold schedule sheet for tracing throughout the project beginning to sample and the mass production.

Here below are some descriptions for your reference:

DFM:

Review the part 2D/3D from customer, will provide the mold layout, material, draft analysis, thickness, tolerance, EJ pins, Sliders, Lifters, Inserts, Surface finish...etc. and/or some suggestions (if any), and then send to you for review and comments/approval.

Mold 3D/2D design:

When the DFM problems are addressed, we start Mold 3D design and send the whole mold design in 3D format (.stp, .x_t, or the formats which you specified), when you approved the 3D design, we can start purchasing steel for manufacturing.

Mold schedule sheet:

The mold schedule sheet will be generated when the Mold 3D/2D is approved, then the mold building starts to count the lead time and will update to you along with manufacturing photos weekly.